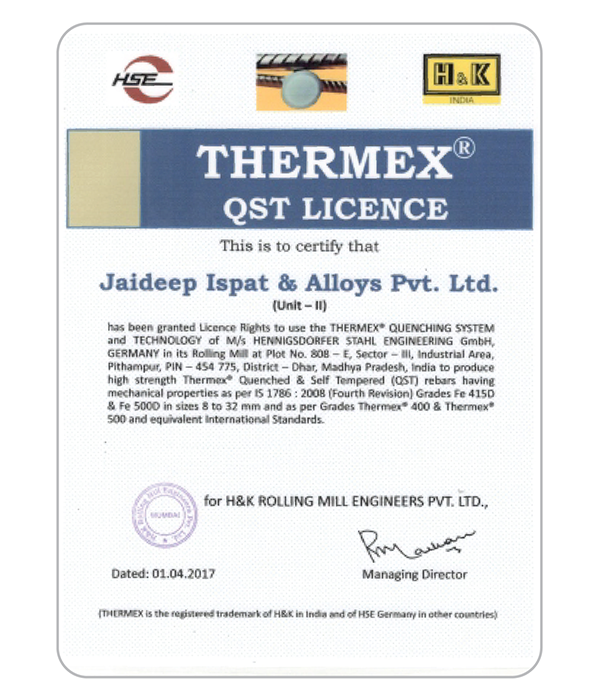

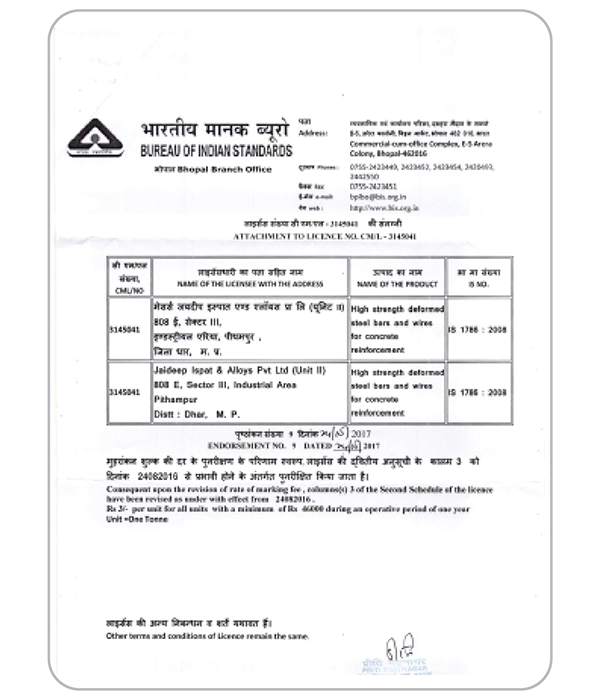

Jaideep Metallics & Alloys Pvt. Ltd. has a completely integrated manufacturing facility at Wada, Maharashtra that is equipped with the latest QST manufacturing technology and Thermex version 3 quenching system.

We produce MS billets at our steel plant which consists of induction furnaces with a continuous caster. The billets are subjected to strict quality controls during production to ensure quality in terms of chemical composition for reinforcement steel. The hot billets are then subjected to a controlled rolling process which ensures a precise diameter and an ideal ribbed pattern perfect for bonding with concrete.

The rolled bars are then rapidly cooled through a very precise and intense inline Thermex system to obtain QST bars – MOIRA TMXTMT bars that are high and consistent in quality.

For the perfect MOIRA TMX bars, we use the best raw materials along with the superior Thermex process.

Raw Material : Testing & Segregation

- Composition testing segregation

- Stocking in separate bins as per quality

Furnace: Conversion Of Raw Material To Molten Metal

- Melting in furnace as per composition

- Testing batches every 30 mins. to ensure consistent quality standards

- Ferro Alloy added to maintain desired quality and composition

- Molten metal is sent for casting

Casting: Molten Metal To Billet

- Temperature & composition check before casting

- Billets of required length produced

- Billets sent to rolling mill to create TMT bars Casting: Molten Metal to Billet

- Temperature & composition check before casting

- Billets of required length produced

- Billets sent to rolling mill to create TMT bars

Quality Tests On Billets: Before Rolling Process

- Weight check with online weighing system

- Temperature check with online pyrometer

- Composition checks

- Rolling process begins if billets pass quality tests

Rolling Mill: Billet To TMT Bars

- Rolled TMT bars pass through Quenching & Tempering process (Thermex Version 3)

- Quality checked every 15 mins. On mechanical properties of the rolled material

- Checks for weight, yield strength, ultimate tensile strength (UTS), bending test, elongation percentage, surface finish.

Cutting, Packing & Storage

- Cooled TMT bars cut to desired length by cold shearing

- Standard of 12 meters per bar, customised length available for large orders

- TMT bars packed in bundles according to size

- Storage of bundles in covered finished goods yard as per grade, size, length & lot number

We take pride as a supplier of the best quality TMT bars. To ensure and consistently provide the highest quality reinforcement bars, we subject our raw materials and finished products to strict physical and chemical checks throughout the manufacturing process.

FULLY EQUIPPED CHEMICAL LABORATORY

STATE-OF-THE-ART PHYSICAL TESTING LABORATORY

HIGHLY SKILLED QUALITY & PRODUCTION TEAMS